Crushed stone vibrating screen mesh , shaker screen , modular sieve pu mesh

- group name

- Polyurethane modular sieve panel

- Min Order

- 10 piece

- brand name

- Hengshui Rongrui Metal Rubber

- model

- Customize

- Nearest port for product export

- Tianjin Port, Qingdao Port, Lianyungang Port, Shanghai Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, Westem Union

- update time

- Sat, 23 Dec 2017 16:04:08 GMT

Paramtents

Advantage Durable, long service life

Packging & Delivery

- 100cm x 100cm x 90cm

-

Min Order10 piece

Briefing

Detailed

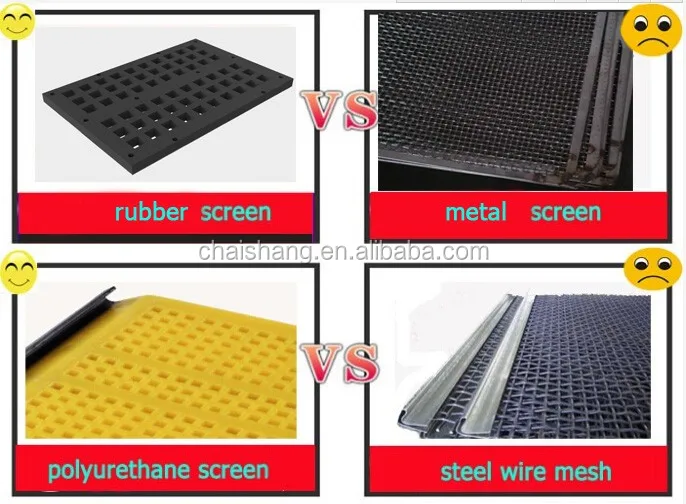

Polyurethane screen with high efficiency, small amplitude, high frequency and other good quality. Is an effective device for fine grained material sieving classification, widely used in iron ore, tin, tungsten, tantalum and niobium ore concentrator screening or classification work.Polyurethane screen mesh offer the highest screening efficiency and are the modern cost effective of achieving improved productivity at reduced maintenance cost in aggregate separation under both wet and dry conditions.

It achieves excellent results with all separation sizes in many applications including: Sand and Gravel, Granite, Quartzite, Silica Sand, Limestone, Coal and Ironworks Materials.

The polyurethane screen are manufactured with integral reinforcement bars parallel to the panel width and selected for each individual application to accurately transmit the dynamic forces of the screening machine and support the bed of the material.

1, Tensile strength, high tear strength, excellent wear resistance, resilience, compression set, long service life.

2, With the metal substrate with strong, not easy from the floor and off.

3, Surface finish, dimensional stability.