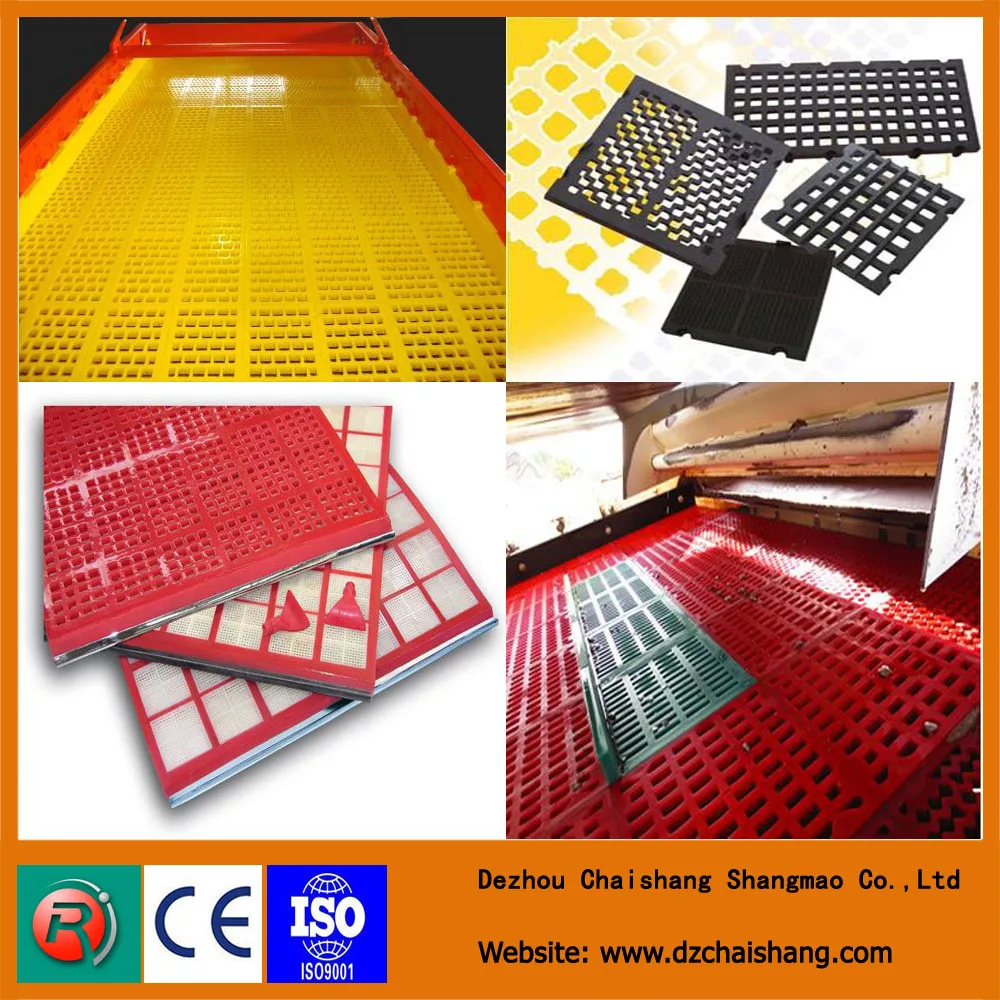

Heavy duty modular screen panels Trommel screen panels

- group name

- Polyurethane fine mesh sieve panel

- Min Order

- 10 piece

- brand name

- Hengshui Rongrui Metal Rubber

- Nearest port for product export

- Tianjin Port, Qingdao Port, Lianyungang Port, Shanghai Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, Westem Union

- update time

- Sat, 23 Dec 2017 16:08:38 GMT

Paramtents

Aperture 5mm-50mm

Advantage Wear-resisting, corrosion resistance, no noise, long service life

Hardness 80-95 shore A

Thickness 5mm-100mm

Packging & Delivery

- 160cm x 160cm x 120cm

-

Min Order10 piece

Briefing

Detailed

When fitting polyurethane skeleton screen mesh panels parallel to the flow of the material, it is usual to stagger each row of panels to prevent transport of fines along continuous plain webs.

When it is not possible to stagger the panels, then the flow of material is diverted by deflectors moulded onto the sides of polyurethane skeleton screen mesh modular panels.

For applications involving severe wear : the primary screening of granite or quartz material then the polyurethane skeleton screen mesh modules are manufactured from a combination of high quality polyurethanes with a highly resilient wear resistant surface supported by a high strength structural polyurethane containing the load carrying reinforcement.

For the classification of fine, moist, sticky materials or screen feeds with a high proportion of near size particles, normally prone to pegging and blinding, the polyurethane skeleton screen mesh modules are fitted with thin perforated polyurethane membranes.

In addition to the main advantages, the polyurethane skeleton screen mesh system can be easily adapted to fit wire cloth for special production purposes. The normal steel bars are replaced with the polyurethane skeleton screen mesh clamp bar assemblies and suitable wire panels.

Light weight reducing weight of screen surface load, can reduce the production unit consumption is for you to save power consumption and prolong the service life of the sieve machine. Easy to install. It can partial replacement, makes change jobs as "easy" to reduce the workload.

Work low noise of the polyurethane screen mesh, polyurethane sieve plate than metal sieve plate can reduce noise 5-20 decibels. Applicability stronger applicability is wide and professional, it is suitable for any type of vibrating screen machine and the mechanisms and quantity. Applications: metallurgy (iron ore, limestone, fluorite, high cooling slag, coke and other raw materials), color, yellow, hydropower engineering, coal, chemical industry, building materials, and abrasive garbage disposal, quarry industry materials such as washing, screening and classification, etc. Various popular format and mesh size of the sieve plate of the new mode, especially in general in impact strength, high hardness, high wear resistance requirements of the occasion. In the iron ore screening, fine grade of raw coal, gold ,copper classification.