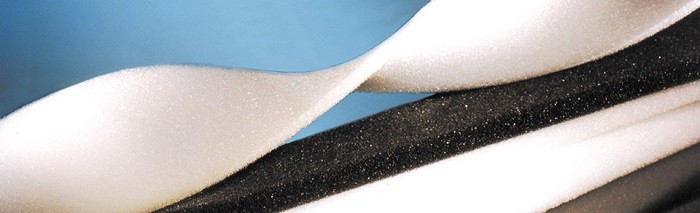

Flexible Polyurethane Foam

time2017/08/26

Flexible Polyurethane Foam

Flexible polyurethane foam (FPF) affects our lives in many ways and new applications are rolling out on a regular basis. It is used as cushioning for a wide variety of consumer and commercial products including furniture, carpet cushion, transportation, bedding, packaging, textiles and fibers. FPF usage consists mostly of slabstock, which is used primarily for carpet cushion and furniture. Most of the remainder is used by the transportation industry for automotive interiors and other purposes.

Furniture

FPF cushions upholstered furniture, office chairs, stadium seating and auditorium seating. As a cushioning material, FPF provides the following benefits:

Support and comfort

Durability

Resiliency

Energy absorption

Handling strength

Carpet Cushion

FPF can also improve the comfort and lifespan of our carpet. By absorbing much of the energy from traffic, FPF protects the carpet face allowing the carpet to look better longer. Its design and construction provides long-term comfort without excessive thickness, maintaining the desired feel underfoot throughout the life of the installation. FPF is used in both residential and commercial applications, the majority of which is supplied by the bonded version of the cushion. Studies have repeatedly shown that polyurethane provides outstanding durability, improves carpet appearance retention, and provides comfort and support to occupants. It helps extend the life cycle extension of the carpet. Polyurethane carpet cushion helps absorb sound by as much as 50 percent—making the workplace quieter and a more productive place through reduced noise distraction, and less fatigue—and the compelling basis for including cushion in the carpet floor covering system is undeniable. There are also environmental benefits: in addition to the fact that bonded polyurethane cushion is made from recycled materials and can be recycled in many localities, the potential extension of carpet life can mean less frequent replacements, resulting in less carpet going to landfill. Some of the many benefits of polyurethane carpet cushion include:

Extended carpet life—carpet cushion can improve the life expectancy of carpet by up to 50 percent

Increased savings and reduced downtime due to less frequent replacement

Added comfort

Reduced ambient noise

Enhanced thermal insulation

Easier carpet maintenance

Recyclable in many localities

Transportation

FPF is used extensively in the transportation industry for seating, headrests, arm rests, HVAC components, interior panels and skins, car and truck fenders, truck beds and support rings for run-flat tires, headliners and other interior systems. Recent developments in polyurethane technology for automotive design are contributing to increased weight reduction, passenger comfort, energy and sound absorption, resiliency, moisture and heat resistance, and compressive strength in vehicles. Polyurethane is increasingly valuable to original equipment manufacturers, also known as OEMs, because it simultaneously offers:

Weight reduction

Sound/vibration absorption

Fuel efficiency

Durability

All of these benefits translate to better gas mileage and a more comfortable ride.

Bedding

FPF is the primary material used today for adding support and comfort to padded bedding products. The industry has produced thicker and larger bedding products. This is evidenced by the increasing popularity of pillow-top mattresses.

FPF is produced in slab or block form and cut to size. Because of its durable comfort and support, ease of fabrication, and adaptability to styling, FPF has become a major component in the bedding industry.

Packaging

FPF provides protection and cushioning to packaged products. Polyurethane foams are often used to package highly sensitive equipment such as electronics, printed circuit boards, jewelry and delicate foods. FPF’s lightweight, water resistance, shock absorption and resiliency make it an attractive application for packaging.

Textiles and Fibers

Nearly a half-century after its development, FPF continues to impact nearly every aspect of our lives. It is also used as insulation for fabric products including clothing. In clothing, FPF provides thermal insulation, tear resistance, fire resistance and light weight to a variety of textiles and fibers including leather products, shoe uppers, tents, life rafts, labels, hand bags, insulation liners and more.