Application of Polyurethane in Mining Industry

time2017/07/18

Application of Polyurethane in Mining Industry

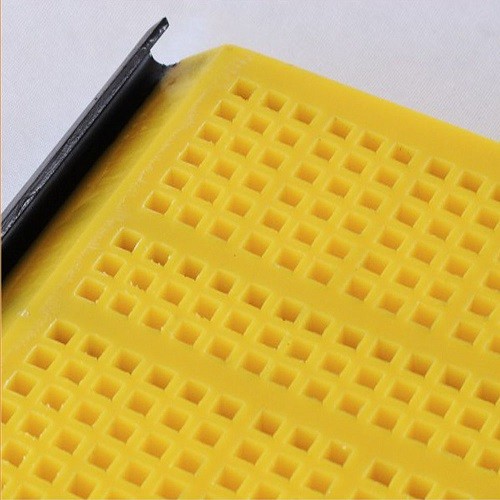

Grouting with polyurethane [PU] resins represents an effective method of improvement of

mechanical and sealing properties of soil and rock environment and constructions. The

principle of grouting technologies is injection of liquid grouting material into the rock

environment or construction under pressure. During the grouting process, fissures and

pores are filled with the grouting material, which subsequently hardens and connects the

disintegrated parts of the rock mass or grains of loose material. Polyurethane grouting

technologies started to be used in the 80s of the 20th century in the mining industry. In the

last recent years, PU grouting technologies spread significantly from the mining

applications to civil engineering and geotechnics. The application possibilities have a rising

tendency and new possibilities occur. Currently, grouting technologies are used mainly in

the following fields:

Mining

strengthening and stabilization of deposit layers before exploitationcrossing of fault zones

securing of the overburden

stabilization of the surrounding of the mine workings

lowering of permeability of the rock mass

strengthening of coal in areas with rock burst risk

limitation of the mine wind blowing

anchoring of soil and rocks

stabilization and sealing of old mine pits and etc.