How is the polyurethane applied?

The polymeric materials known as polyurethanes form a family of polymers which are essentially different from most other plastics in that there is no urethane monomer and the polymer is almost invariably created during the manufacture of a particular object.

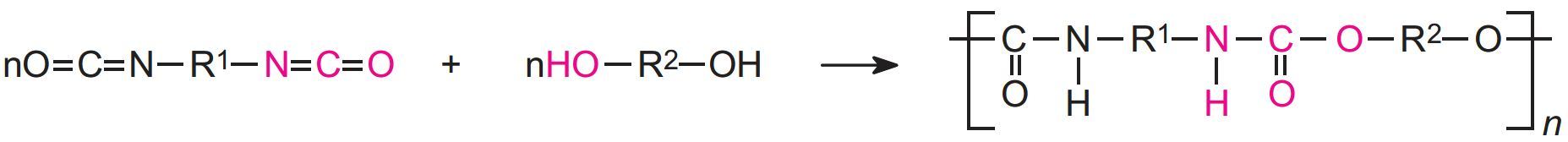

Polyurethanes are made by the exothermic reactions between alcohols with two or more reactive hydroxyl (-OH) groups per molecule (diols, triols, polyols) and isocyanates that have more than one reactive isocyanate group (-NCO) per molecule (diisocyanates, polyisocyanates). For example a diisocyanate reacts with a diol:

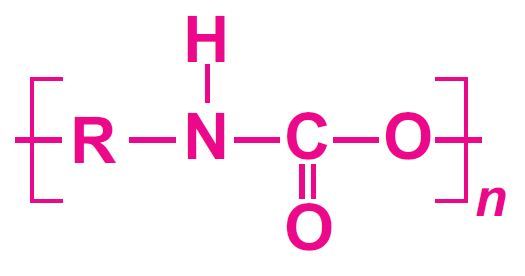

The group formed by the reaction between the two molecules is known as the 'urethane linkage'. It is the essential part of the polyurethane molecule.

Uses of polyurethanes

The physical properties, as well as the chemical structure, of a polyurethane depend on the structure of the original reactants, in particular the R1 and the R2 groups. The characteristics of the polyols - relative molecular mass, the number of reactive functional groups per molecule, and the molecular structure - influence the properties of the final polymer, and hence how it is used.

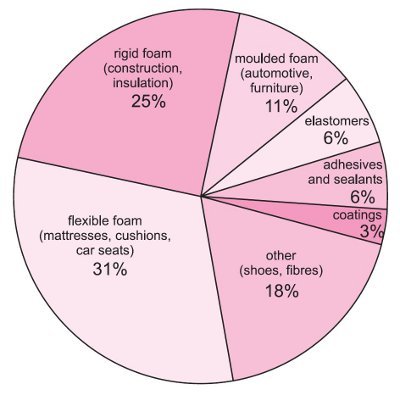

Figure 1 Uses of polyurethanes.

There is a fundamental difference between the manufacture of most polyurethanes and the manufacture of many other plastics. Polymers such as poly(ethene) and poly(propene) are produced in chemical plants and sold as granules, powders or films. Products are subsequently made from them by heating the polymer, shaping it under pressure and cooling it. The properties of such end-products are almost completely dependent on those of the original polymer.

Polyurethanes, on the other hand are usually made directly into the final product. Much of the polyurethanes produced are in the form of large blocks of foam, which are cut up for use in cushions, or for thermal insulation. The chemical reaction can also take place in moulds, leading to, for example, a car bumper, a computer casing or a building panel. It may occur as the liquid reactants are sprayed onto a building surface or coated on a fabric.

Figure 2 No other plastic allows itself to be made to measure in the same way as a polyurethane. Foams can be flexible or rigid, resistant to cold or particularly kind to skin. It all comes down to the way in which the polyurethane 'building blocks' are blended.